Headers for 4WD K5 Blazer

The first generation 1969-72 K5 Blazer and 1970-72 GMC Jimmy are beautiful classic full-size sport utility vehicles. They are functional, easily modified or restored, and have always held a high value of popularity. The ’72 is my preference, and GM really turned a great design into something bland with the second generation Blazer body design.

One modification some will consider is to swap out the small block Chevy engine for a big block. This swap is fairly straightforward if the desire is to keep the original TH350 or original manual transmission. The swap process goes a bit sideways when someone wishes to deviate from the factory transmissions. One such example is using the TH400 transmission.

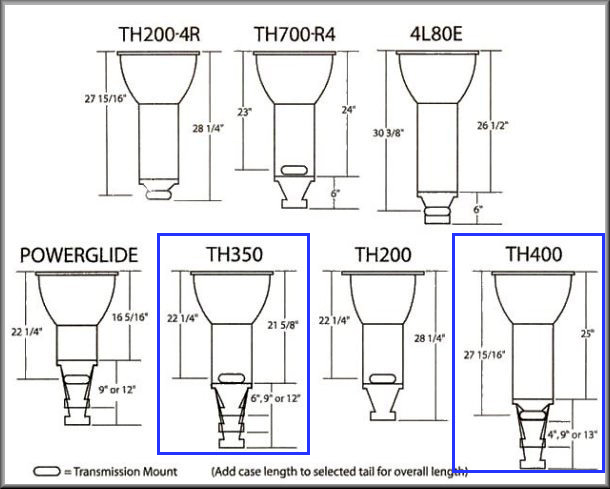

The thought of swapping out the TH350 for a TH400 seems reasonable. The TH400 is slightly stronger, and better suited for the higher torque of the big block, the vehicle weight, taller tires, etc. That is until we realize the difference in overall case length. Suddenly, sneaking in the TH400 for the TH350 becomes a bit more complicated.

Since we are unable to move the differential around, this longer transmission is going to require changing a few more components. The most recognized initial concern is the transmission cross member and a new mount location. However, that does not address the actual increase in transmission case length. We now have an engine that is not only larger by all definitions, the TH400 is moving it forward in the chassis.

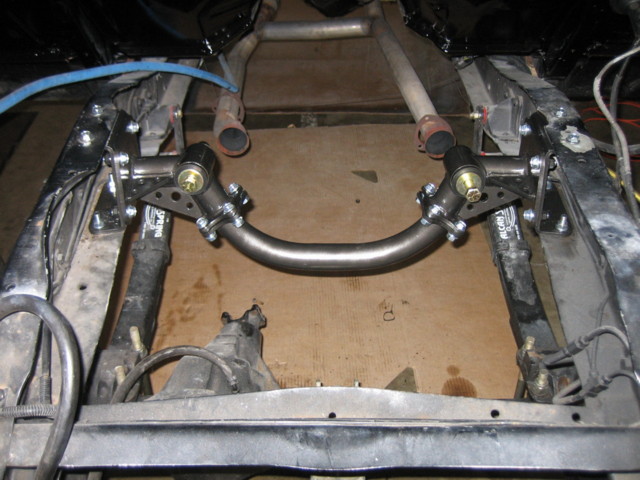

Moving the engine forward is partially simplified by using an aftermarket cross member and motor mount kit like the one from DIY4x. (image examples below)

The DIY4X kit locates the engine into the proper position. However, do not drill or permanently mount anything without having all of the remaining critical pieces of this puzzle and test-fitting all of them together first. This includes:

- Radiator

- Engine Accessories

- Exhaust Headers

- Starter

Exhaust Header Availability

Here is the focus of this post. A gentleman recently reached out to us regarding a ’72 K5 Blazer project he was working on, and was specifically looking for any header set that would fit. He originally asked about the Sanderson BB8 header set for big block Chevy truck applications and I advised him that it wasn’t even worth trying because I knew it would not fit. He then mentioned having seen something on a web forum some time ago that described a similar swap and that person had used a mix-matched pair of Sanderson full-length headers. That triggered one or two possible combinations that I thought “might” work. I asked if he knew where that forum post was so I could review it or see images of the headers that were used. He said he would try and find it and I also started looking, as well as reaching out to Sanderson to see if they remembered anything about that project.

He was able to find the original post and provide additional information on the Sanderson part numbers. This other person had tried a few different header combinations before determining through trial and error that a driver side Sanderson C6 and passenger side C7 fit as if they were destined for the application. View the gallery at the bottom of this post to see the progress.

After I found out that this was actually the perfect combination I worked with Sanderson and created a new part number for this header set. This is now Sanderson part #C8.

New Sanderson Header Part Number

There are a few more considerations to be aware of.

- The TH400 uses a 168-tooth flywheel. Be sure to use a compatible mini-starter. We recommend the PowerMaster 9540, 9600, or compatible. These starters feature 360° clocking and a design that offers the most header clearance.

- Shimming of the DIY4X cross member or mounts may be required to achieve proper header-to-frame clearance. This application required a 1/2″ shim on either side.

- A frame-to-block driver side torque limiter is recommended.

-

Exhaust Headers

Sanderson C8 Full-Length Big Block Chevy Header Set

$519.00 – $785.00 Select options