Why Header Wraps Destroy Headers

We are regularly asked or have commented on the use of header wraps (header tape, thermal tape, heat tape) on exhaust header systems. This issue is a real pet peeve of mine. Good or bad about a product I will give my opinion based upon direct use and fact, and this stuff screams “Do Not Use on Exhaust Headers!”

The Facts

- Header wraps are designed to keep the heat in the header to improve scavenging of the cylinders. Keeping the heat in the header allows the exhaust speed to remain high. (the right idea)

- Header wraps, by keeping the heat in the header, also reduces the radiant heat in the engine bay.

- There are no header manufacturers that I know of who will warranty their headers if header wrap has been installed on their products. This includes partial installations of the header tape on certain tubes or sections.

- In most cases, the header wrap damages the headers beyond repair. (I will explain below)

- If you run a lean mixture, you “may” see a slim performance gain using header wraps. A rich mixture may show slim to absolutely NO gain in performance.

- If replacing your headers and header gaskets regularly does not bother your wallet or your time, and you like that ugly look of a wrapped header, go ahead and use the heat wrap.

Background Information

Temperature Readings, Taken at Daytona Motor Speedway

| Measure Location: | JET-HOT® Coated | No Coating | Coated Difference |

|---|---|---|---|

| 1.0" From Engine | 300°F, (149°C) | 750°F, (399°C) | -450°F, (-232°C) |

| 2.0" Above header tube | 210°F. (99°C) | 300°F, (149°C) | -90°F, (-32°C) |

| 1.0" Above Floor Pan (inside vehicle) | 115°F, (46°C) | 165°F, (74°C) | -50°F, (-10°C) |

Pretty impressive improvement in temperature reduction! With any coating it is important to not damage the coating. The thermal coating becomes part of the header material. Most of the other coating brands are comparable to these figures —as long as they are multi-layer, applied both inside and outside of the tubes and using proper materials. NOTE: Most “inside” tube coating applications will not cover the entire inside of each tube, as they are limited by the length of the application wand. This is not a problem.

Something Most Racers/Car Owners Don't Realize

Headers Oxidize!

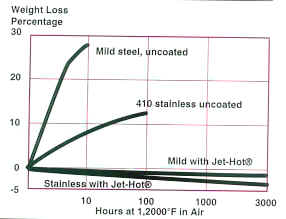

- Mild Steel (1010) uncoated header exposed to continuous 1200º F. in normal air will have a weight loss percentage of roughly 25% with only 10 hours use at this temperature.

- Stainless Steel (410) uncoated header will have roughly 8% weight loss in the same 10 hour period.

-

A coated mild steel header will have NO weight loss at temperatures up to 1200º F. In fact it will actually gain a bit of weight! Between 1300º F and 1600º F the coating will begin to show signs of mud cracking or like the look of lacquer checking. However, limited diffusion takes place between the coating and the substrate, producing a very thin film of iron aluminide, which continues to inhibit oxidation.

Now, consider the information provided above and the added thermal stress generated by the header wraps. What do you see? Remember that the wrapped metal cannot cool properly and the header wrap is causing the material to super-heat and leads to premature component failure!

Side Note: Step Headers

Step headers are designed to allow controlled and efficient exhaust gas expansion within a selected engine RPM range. What does this mean? As exhaust gases are exiting the cylinder head exhaust ports and into the header they are still burning, and these gases are rapidly expanding down the primary tubes. In fact, they are “pulsing”. If the header is designed to take advantage of the pulse expansions of the exhaust gases, gains in horsepower and torque will occur. However, this needs to be done right and with proper research and scinece, or else that $1500.00 or more set of custom step headers is a big waste of money. When designing a step header, it is important to know where maximum power is needed, and since each step header is often RPM-specific to each engine combination.

DEFINITION: A “STEP” is an increase in primary tube diameter.

| Header Type | Primary Tube Diameter | Primary Step Length | Second Step Diameter | Second Step Length | Third Step Diameter | Third Step Length |

|---|---|---|---|---|---|---|

| Single Size Tubing | 1.757" | 31.9" - 34.4" | ----- | ----- | ----- | ----- |

| 2-Step Header | 1.757" | 14.0" - 16.5" | 1.882" | 15.4" - 17.9" | ----- | ----- |

| 3-Step Header | 1.632" | 14.0" - 16.5" | 1.757" | 6.8" - 9.3" | 1.882" | 6.1" - 8.6" |

Collector Specs:

3.221″ Diameter with a 18.0: to 23.0″ length (2nd best = 9.0: to 11.5″ length)

Acoustical Tuning Specs:

-

- best wave = (- negative pressure) = 5,000 – 6,000 RPMs

- bad wave = (+ positive pressure) = 2,018 – 3,518 RPMs

- wav-lag degrees = 3.2º – 6.3º

Experiencing the Negative Effects of Header Wraps

Because of the expanding exhaust gases, if you have had the experience (as I have) to see first hand what header wrap has done to a header (a few example images provided below), you would notice the locations on a header where the material failures occur. This is typically where a step (in a step header) would be located, or where there is an expansion pulse of exhaust gases inside the header tube. I have held headers in my hands where literally the only thing keeping the header in one piece was the wrap. Whole chunks of the header material was gone, simply melted away. If you were to speak to some “engineers” (I use that title with caution) they will probably tell you that aliens stole the metal as the car was racing around the track! They say this because the conclusion that the wrap is causing problems is not part of normal metallurgy and thermal dynamics theory. The header wrap allows temperatures between the wrap and the header (explained above) to turn the material molten. Once molten it can separate.

Here are a few examples of what happens to a header using tape / thermal wrap:

This particular customer initially claimed, when requesting warranty replacement, that he did not use header wraps. The tape wrap marks on the header clearly show that was not the truth.

Have questions regarding this information?

Or, call our dedicated support staff at (775) 746-4887

Please review other helpful tech articles